Letter from the Chairman

x

Shareholders,

Italy finally started to emerge from recession in 2015, although

the signs of recovery, after the years of crisis following the collapse

of Lehman Brothers in 2007, are still tentative, not just for the this

country, but for the world’s entire economic system. During the year,

emerging countries, and particularly Brazil, continued to slowdown, and

the Russian economy significantly weakened. Similarly, China, which

remains the country that mostly influences the world development, was

affected by the crisis: despite still experiencing, together with India,

far higher growth rates than the western economies, the country is

showing a slow but steady slowdown. By contrast, the United States

confirmed that it has entered a phase of stable, albeit modest, growth,

whilst the euro countries, including Germany, have not yet rediscovered

the necessary momentum for a genuine recovery able to free Europe

from the quagmire in which it finds itself.

The car market, which generates three quarters of Brembo’s turnover,

recorded a 2% increase at global level, almost half the previous year’s

figure but still positive, thanks primarily to China, Western Europe and

the United States. The Chinese market confirmed itself as the world’s

top car market, even though growth was more moderate (+5.3%)

than in recent years. Western Europe consolidated the change of

direction started in 2014 and almost doubled the growth rate (+9%),

with particularly high peaks in Italy and Spain, and with Germany in first

place in terms of sales volumes. Eastern European countries — apart

from Russia, which fell by almost 36% — again reported double-digit

growth (+12.1%), though lower than in 2014. A positive trend continued

in the United States (+5.8%) whilst, with reference to the Company’s key

markets, Brazil, Argentina and Japan reported a sharp decline.

For Brembo 2015 was another highly positive year, confirming the

Group’s ability to continue on its path of growth and value creation,

albeit in a still turbolent world economic context. In the year, revenues —

which have more than doubled in five years — exceeded €2,073 million,

up by 15% compared to 2014. Gross operating profit reached nearly

€360 million, increasing by 28.6%, whereas net profit was €184 million,

up by 42.5% compared to the previous year. At year-end, net debt

amounted to €160.7 million, improving by €109.7 million compared to

31 December 2014. These figures show, amongst other things, how

Group profitability has grown significantly more than turnover. This

testifies to Brembo’s effective optimisation of its production processes.

Contributing to these results are both the Italian and European

business components and those in other key geographical areas,

such as the United States and China, where Brembo has developed

a keen investment strategy in recent years,

establishing itself as a global player able to

operate on worldwide markets. Today, the

Group employs nearly 10,000 people, including

some hundreds new recruits, of whom 270 in

Italy, and currently operates in 15 countries

on 3 continents through its manufacturing

and commercial sites. Apart from Italy,

manufacturing plants are located in Germany,

Poland, the United Kingdom, the Czech

Republic, the United States, Mexico, Brazil,

Argentina, China and India. An additional €154

million was invested in 2015 alone, of which

more than €40 million in Italy, which continues

to be one of the countries in which Brembo

invests most in research and development

and to maintain technologically cutting-edge

plants. The remaining amount was invested

primarily in Central-North America, China,

Poland and the Czech Republic.

In North America, works are nearing completion

on the building of a cast-iron foundry

in Michigan, close to the new Homer facilities,

which will begin operations in the first months

of 2016, thus allowing Brembo to start a

vertical integration process of its production

capacity in the United States as well. In Mexico,

a new foundry and plant for aluminium caliper

processing and assembly were inaugurated in

October 2015, to supply original equipment to

the major European, Asian and Central-North

American manufacturers.

In Eastern Europe, investments aimed at

increasing production capacity are still underway

in the integrated industrial hubs in Dabrowa

Górnicza (Poland) and Ostrava-Hrabová

(Czech Republic), devoted respectively to

the casting and processing of brake discs

for cars and commercial vehicles, and the

casting, processing and assembly of brake

calipers and other aluminium components.

A new investment plan was also launched

at the same time that will be developed from 2014 to 2017, for a

total expenditure of approximately €34 million, aimed at starting

up a new plant in Niepolomice (Poland) specialising in the

processing of steel disc hats to be assembled onto the

light discs manufactured at the Group’s plants located in

Poland, China and the United States.

In China, where Brembo has been successfully

operating for many years through its own plants,

an agreement was signed in September 2015 to

acquire a majority stake in Asimco Meilian Braking

System Co. Ltd., a Chinese company that owns

a foundry and a plant for the manufacturing of

cast-iron brake discs. This company supplies

regional car makers, mainly including joint

ventures between Chinese companies and

European and U.S. top players.

The significant cash generation reported by

the Group enables us to face, from a position of

strength, a new cycle of investments in support

of future growth, with the aim of further expanding

our production capacity — particularly in China

and the United States — and improving our

research and development activities to maintain

and consolidate the leadership in technology

and innovation that has always distinguished

us. In this regard, Brembo is primarily focused on

mechatronic systems for the plants of the future

and the development of new materials. This means

laying the foundations for the next ten years, which

will see a sharp rise in vehicle electrification alongside

a significant brake system integration and a ongoing

search for weight-reduction solutions. Our achievements

and the new opportunities that are currently marking the

automotive industry allow us to look to the future with

prudent optimism. This is also because behind the positive

figures lies the strong commitment of Brembo’s management

and all those who, in Italy and throughout the world, work

capably, passionately and intelligently within the Group to

achieve constantly changing and challenging goals.

Plants, Technical and sales department and Research and development center

BREMBO NORTH AMERICA INC.

WILMINGTON, DELAWARE (USA)

Activities: development, production and sale of brake discs for car original equipment and the aftermarket, and braking systems for cars, motorbikes and the racing sector.

Brembo North America Inc. is based in Homer, Michigan. It produces and sells OEM and aftermarket brake discs, as well as high-performance car braking systems. In 2010, a Research and Development Centre was opened at the facility in Plymouth (Michigan) to develop and market new solutions in terms of materials and designs for the U.S. market, backed by Brembo S.p.A. and local technical staff.

Net sales for 2015 amounted to USD 467,501 thousand (€421,314 thousand) compared to net sales amounting to USD 422,649 thousand (€318,058 thousand) for the previous year.

Net income was USD 34,361 thousand (€30,966 thousand) at 31 December 2015, compared to net income of USD 20,921 thousand (€15,744 thousand) for 2014.

At the end of the year, the workforce numbered 560, an increase of 34 compared to the end of 2014.

Plants and Technical and sales department

BREMBO MÉXICO S.A. DE C.V.

APODACA (MEXICO)

Activities: production and sale of car brake discs for original equipment and the aftermarket and braking systems for cars and commercial vehicles.

As a result of the merger with Brembo México Apodaca S.A. de C.V. in 2010, the company is now 51% owned by Brembo North America Inc. and 49% owned by Brembo S.p.A.

In 2015, net sales amounted to USD 103,948 thousand (€93,679 thousand), with a net income of USD 4,554 thousand for the year (€4,104 thousand). In 2014, net sales amounted to USD 98,035 thousand (€73,774 thousand), with a net income of USD 7,029 thousand (€5,290 thousand).

The workforce numbered 353 at 31 December 2015, compared to 263 at the end of 2014.

Plants and Technical and sales department

BREMBO DO BRASIL LTDA.

BETIM (BRAZIL)

Activities: production and sale of brake discs and flywheels for the original equipment market.

The company is headquartered in Betim, Minas Gerais, and promotes the presence of Brembo in the South American original-equipment market for car brake discs. The company also produces flywheels for the car industry in the Santo Antônio de Posse plant.

Net sales for 2015 amounted to BRL 156,642 thousand (€42,432 thousand), with a net loss of BRL 76,134 thousand (€20,624 thousand). In 2014, net sales amounted to BRL 186,704 thousand (€59,788 thousand), with a net loss of BRL 38,705 thousand (€12,394 thousand).

The workforce numbered 333 at 31 December 2015, compared to 503 at the end of the previous year..

Plants and Technical and sales department

BREMBO ARGENTINA S.A.

BUENOS AIRES (ARGENTINA)

Activities: production and sale of car brake discs for the original equipment market.

The company is based in Buenos Aires, Argentina. Brembo acquired a 75% stake in the company in 2011. Under the agreement, Brembo exercised an option right on the remaining 25% in 2013; therefore, the company is currently fully owned by the Brembo Group.

Net sales amounted to ARS 191,205 thousand (€18,655 thousand), with a net loss of ARS 29,447 thousand (€2,873 thousand). In 2014, net sales amounted to ARS 199,546 thousand (€18,520 thousand) and net loss to ARS 13,188 thousand (€1,224 thousand).

The workforce numbered 124 at 31 December 2015, one more compared to 31 December 2014.

Plants and Technical and sales department

CORPORACION UPWARDS ‘98 S.A.

SARAGOZZA (SPAIN)

Activities: sale of brake discs and drums for cars, distribution of the brake shoe kits and pads.

The company carries out sales activities only.

Net sales for 2015 amounted to €26,942 thousand, compared to €20,853 thousand for 2014. Net income amounted to €420 thousand compared to a net income of €1,509 thousand reported for 2014.

The workforce numbered 71 at 31 December 2015, compared to 69 at the end of 2014.

Plants and Technical and sales department

AP RACING LTD.

COVENTRY (UNITED KINGDOM)

Activities: production and sale of braking systems and clutches for road and racing vehicles.

AP Racing is the market leader in the production of brakes and clutches for racing cars and motorbikes. The company designs, assembles and sells cuttingedge, high-tech products throughout the world for the main F1, GT, Touring and Rally teams. It also produces and sells original equipment brakes and clutches for prestige car manufacturers.

Net sales for 2015 amounted to GBP 38,083 thousand (€52,457 thousand), compared to GBP 36,700 thousand (€45,509 thousand) in 2014. In the reporting year, net income amounted to GBP 3,882 thousand (€5,348 thousand), compared to GBP 3,906 thousand (€4,844 thousand) in 2014.

The workforce numbered 126 at 31 December 2015, unchanged compared to the end of 2014.

Technical and sales department

BREMBO DEUTSCHLAND GMBH

LEINFELDEN – ECHTERDINGEN (GERMANY)

Activities: purchase and resale of vehicles, technical and sales services.

The company, which is 100% owned by Brembo S.p.A., was formed in 2007. It specialises in buying cars for tests and encouraging and simplifying communication between Brembo and its German customers in the various phases of project planning and management.

At 31 December 2015, net sales amounted to €209 thousand (€200 thousand for 2014), with a net income of €28 thousand (€60 thousand for 2014).

The company has no employees and uses outside consultants only.

Plants, Technical and sales department and Research and development center

Brembo S.P.A.

CURNO (ITALY)

Activities: analysis, design, development, application, production, assembly and sale of braking systems, light alloy castings for various sectors, including the car and motorbike industries.

Brembo S.p.A. closed 2015 with sales of goods and services amounting to €780,802 thousand, up 9.5% compared to €713,357 thousand in 2014. The item “Other revenues and income” amounted to €32,984 thousand in 2015 compared to €26,904 thousand in 2014, whereas capitalised development costs in the year amounted to €11,326 thousand.

Gross operating income went from €85,832 thousand (12.0% of sales) in 2014 to €112,156 thousand (14.4% of sales) in 2015. Net operating income, after depreciation, amortisation and impairment losses of property, plant, equipment and intangible assets amounting to €34,859 thousand, closed at €77,297 thousand compared to €48,713 thousand for the previous year.

Net interest expense from financing activities amounted to €3,767 thousand, compared to €6,330 thousand for 2014. Income from shareholdings amounted to €54,508 thousand and was mainly attributable to the distribution of dividends by some subsidiaries (Brembo Poland Spolka Zo.o., Brembo Scandinavia A.B., AP Racing Ltd., Brembo Russia LLC. and Brembo SGL Carbon Ceramic Brakes S.p.A.). During the reporting year, net income amounted to €103,313 thousand, compared to €68,824 thousand in 2014.

The workforce numbered 2,971 at 31 December 2015, increasing by 111 compared to 2,860 at the end of 2014.

Plants and Technical and sales department

LA.CAM (LAVORAZIONI CAMUNE) S.R.L.

STEZZANO (ITALY)

Activities: precision mechanical processing, lathe work, mechanical component production and similar activities, on its own account or on behalf of third parties.

The company was incorporated by Brembo S.p.A. in 2010. In the same year it leased two companies from an important Brembo Group’s supplier that was experiencing financial difficulties. The goal was to safeguard the continuity of supply, the expertise and technological assets obtained by these companies in their many years of collaboration with the Group. The lease transaction involved Immc S.n.c. and Iral S.r.l. These companies specialise in processing aluminium, steel and cast-iron pistons for brake calipers intended for use in the car, motorbike and industrial vehicle sectors, and in the production of other types of components, including small high-precision metallic parts and bridges for car brake calipers, as well as aluminium caliper supports for the motorbike sector, chiefly produced for the Brembo Group. In 2012, La.Cam. acquired the business units of both companies.

In 2015, net sales amounted to €35,872 thousand compared to €32,329 thousand in 2014, referring mainly to Brembo Group companies. Net income for 2015 was €993 thousand, compared to a net income of €489 thousand at the end of 2014.

The workforce numbered 198 at 31 December 2015, compared to 205 for the previous year.

Plants and Technical and sales department

BREMBO SGL CARBON CERAMIC BRAKES S.P.A.

STEZZANO (ITALY)

Activities: design, development, production and sale of carbon ceramic brake discs.

As a result of the joint venture agreements finalised in 2009 between Brembo and SGL Group, the company is 50% owned by Brembo S.p.A. and in turn controls 100% of the German company Brembo SGL Carbon Ceramic Brakes GmbH. Both companies carry out design, development, production and sale of braking systems in general, and particularly of OEM carbon ceramic brake discs for top-performance cars, as well as research and development activities concerning new materials and applications.

Net sales at 31 December 2015 totalled €52,784 thousand, up compared to €44,689 thousand in 2014. In the reporting year, net income amounted to €7,746 thousand compared to net income of €12,161 thousand in 2014.

The workforce numbered 130 at 31 December 2015, 19 more than at the end of 2014.

Research and development center

PETROCERAMICS S.P.A.

MILANO (ITALY)

Activities: research and development of innovative technologies for the production of technical and advanced ceramic materials, geomaterial processing and rock mass characterisation.

Brembo S.p.A. acquired 20% of this company by subscribing a capital increase in 2006.

Net sales for 2015 amounted to €1,594 thousand, with a net income of €58 thousand. In 2014, net sales were €1,840 thousand and net income amounted to €372 thousand.

Technical and sales department

BREMBO SCANDINAVIA A.B.

GÖTEBORG (SWEDEN)

The company promotes the sale of brake discs for the car sector, destined exclusively for the aftermarket. Net sales for the reporting year amounted to SEK 8,404 thousand (€898 thousand), with a net income of SEK 2,845 thousand (€304 thousand), compared to net sales of SEK 6,710 thousand (€738 thousand) and net income of SEK 1,080 thousand (€119 thousand) for 2014.

The workforce numbered 1 at 31 December 2015, unchanged compared to the same date of the previous year.

Plants and Technical and sales department

BREMBO POLAND SPOLKA ZO.O.

DABROWA-GÓRNICZA (POLAND)

Activities: development, casting, production and sale of brake discs and braking systems for cars and commercial vehicles.

On 1 October 2014, the merger of Brembo Spolka Zo.o. into Brembo Poland Spolka Zo.o., both wholly owned by Brembo S.p.A., became effective. The transaction was aimed at corporate streamlining, better organisational flexibility and rationalisation of structural costs.

The company produces OEM braking systems for cars and commercial vehicles in the Czestochowa plant. In the Dabrowa-Górnicza plant, it has a foundry for the production of cast-iron discs destined for use in its own production plant or by other Group companies. The Niepolomice plant processes steel disc hats to be assembled onto the light discs manufactured at the Group’s plants located in China, the United States, and in the Dabrowa-Górnicza plant as well.

In 2015, net sales amounted to PLN 1,559,500 thousand (€372,838 thousand), compared to PLN 1,421,046 thousand (€339,600 thousand) for 2014. At 31 December 2015, net income was PLN 343,609 thousand (€82,148 thousand), compared to PLN 272,547 thousand (€65,133 thousand) for the previous year.

The workforce numbered 1,581 at the end of the year, compared to 1,562 at the end of 2014.Technical and sales department

BREMBO RUSSIA LLC.

MOSCA (RUSSIA)

Activities: promotion of the sale of car brake discs.

Founded in July 2014, the Moscow-based company is wholly owned by Brembo S.p.A. It promotes the sale of car brake discs for the aftermarket.

Net sales reported by the company amounted to RUB 24,965 thousand (€367 thousand) compared to RUB 6,195 thousand (€121 thousand) in 2014; net income was RUB 8,697 thousand (€128 thousand) compared to RUB 304 thousand (€6 thousand) at 31 December 2014.

The workforce numbered 2 at the end of the year, unchanged compared to the end of 2014.

Plants and Technical and sales department

BREMBO CZECH S.R.O.

OSTRAVA-HRABOVÁ (CZECH REPUBLIC)

Activities: casting, production and sale of braking systems for cars.

The company was formed in 2009 and started its production activity in 2011. It carries out the casting, processing and assembly of brake calipers and other aluminium components.

In 2015, net sales amounted to CZK 6,428,851 thousand (€235,618 thousand) compared to CZK 5,066,962 thousand (€184,013 thousand) in 2014, closing the year with a net income of CZK 437,062 thousand (€16,018 thousand) compared to a net income of CZK 247,214 thousand (€8,978 thousand) in 2014.

The workforce numbered 788 at 31 December 2015, increasing compared to 614 for the previous year.

Plants

BREMBO BEIJING

BRAKE SYSTEMS CO. LTD.

PECHINO (CHINA)

Activities: promotion and development of the Chinese market.

Fully owned by Brembo S.p.A., the company sold its 31.12% stake in Brembo Nanjing Brake Systems Co. Ltd. to its Parent Company in 2014. It subsequently changed its company name from Brembo China Brake Systems Co. Ltd. to the current Brembo Beijing Brake Systems Co. Ltd.

At 31 December 2015, it did not report any sales. The net loss at 31 December 2015 was CNY 365 thousand (€52 thousand), compared to a net income of CNY 26,141 thousand (€3,193 thousand) for 2014 attributable to the gain from the sale of the stake in BNBS Co. Ltd. to Brembo S.p.A.

At the end of the year, the company had no employees.

Plants, Technical and sales department and Research and development center

BREMBO NANJING BRAKE SYSTEMS

CO. LTD.

NANCHINO (CHINA)

Activities: development, production and sale of car brake discs for original equipment and braking systems for cars and commercial vehicles.

The company, a joint venture between Brembo S.p.A. and the Chinese group Nanjing Automobile Corp., was formed in 2001. Brembo Group acquired control over the company in 2008. In 2013, Brembo Group acquired full control from the Chinese partner Donghua Automotive Industrial Co. Ltd.

At 31 December 2015, net sales amounted to CNY 756,262 thousand (€108,456 thousand) and net loss was CNY 701 thousand (€101 thousand); in 2014, sales amounted to CNY 667,154 thousand (€81,477 thousand) and net loss was CNY 6,377 thousand (€779 thousand).

The workforce numbered 284 at 31 December 2015, compared to 222 at the end of 2014.

Plants and Technical and sales department

BREMBO NANJING FOUNDRY CO. LTD.

NANCHINO (CHINA)

Activities: production and sale of foundry products for the automotive market, including the aftermarket.

The company, set up in 2009 and 100% held by Brembo S.p.A., acquired the foundry activities in 2010 from the Chinese company Donghua. The aim was to develop together with the company Brembo Nanjing Brake Systems Co. Ltd. an integrated industrial hub, including foundry and manufacture of brake calipers and discs for the car and commercial vehicle markets.

Net sales amounted to CNY 335,378 thousand at 31 December 2015 (€48,097 thousand), with a net income of CNY 4,364 thousand (€626 thousand), compared to net sales of CNY 359,999 thousand (€43,965 thousand) and a net income of CNY 87,258 thousand (€10,657 thousand) for 2014.

The workforce numbered 207 at 31 December 2015, compared to 175 at the end of 2014.

Technical and sales department

QINGDAO BREMBO TRADING CO. LTD.

QINGDAO (CHINA)

Activities: logistics and sales activities in the economic and technological development hub of Qingdao.

Formed in 2009 and fully controlled by Brembo S.p.A., the company carries out logistics and sale activities within the Qingdao technological hub.

thousand (€21,565 thousand), compared to CNY 130,452 thousand (€15,932 thousand) for the previous year. Net income for the year was CNY 4,414 thousand (€633 thousand), up compared to CNY 3,228 thousand (€394 thousand) for 2014.

The workforce numbered 21 at 31 December 2015, six more than at the same date of 2014.

Technical and sales department

BREMBO JAPAN CO. LTD.

TOKYO (JAPAN)

Activities: sale of braking systems for the racing sector and original equipment for cars.

Brembo Japan Co. Ltd. is Brembo’s commercial company that handles the Japanese racing market. Through the Tokyo office, it provides primary technical support to the OEM customers in the area. It also renders services to the other Group companies operating in Japan.

Net sales for 2015 amounted to JPY 587,030 thousand (€4,371 thousand), compared to JPY 595,475 thousand (€4,242 thousand) in 2014. Net income for the reporting year amounted to JPY 54,342 thousand (€405 thousand), compared to JPY 50,246 thousand (€358 thousand) in 2014.

The workforce numbered 15 at 31 December 2015, one less than at the end of 2014.

Plants and Technical and sales department

BREMBO BRAKE INDIA PVT. LTD.

PUNE (INDIA)

Activities: development, production and sale of braking systems for motorbikes.

The company is based in Pune, India, and was originally set up in 2006 as a joint venture held in equal stakes by Brembo S.p.A. and the Indian company Bosch Chassis Systems India Ltd. Since 2008, the company has been wholly owned by Brembo S.p.A.

55,625 thousand), with a net income of INR 278,236 thousand (€3,909 thousand). In 2014, net sales amounted to INR 3,581,747 thousand (€44,182 thousand), with a net income of INR 276,109 thousand (€3,406 thousand).

The workforce numbered 232 at 31 December 2015, compared to 230 at 31 December 2014.

CAST-IRON DISCS

xNew calculation and simulation methodologies continued to be developed for cast-iron discs, focused on identifying and optimising technical and process parameters. The R&D departments (technical and foundry) have started the joint development of a simulation methodology which also includes process parameters that may influence the disc’s vibratory capacities (own frequencies). The first simulations were successfully completed in the second half of 2015. In the future, this will allow Brembo to define with even greater accuracy, early in the design stage, the qualities that could improve the brake system’s comfort characteristics.

A new technical solution also continued to be developed to significantly reduce problems related to vehicle comfort, with the production of prototypes for an application development currently in the testing stage.

Work has also continued on improving the performance of cast-iron discs on heavy commercial vehicles. The study of new geometries has resulted in a significant reduction in mass and an improvement in the disc’s cooling and ventilation capacity, with a consequent reduction in the braking system’s operating temperatures. The new technical solutions have been patented and are in the application development stage with various customers.

Product and process improvement work is progressing for cast-iron discs for car applications. These will be subsequently introduced in normal application developments for the world’s leading car manufacturers.

Particular attention is paid to reducing disc weight, which translates into a reduction in fuel consumption and the resultant environmental impact of the car (lower CO2 emission), a factor that drives the automotive market and all of Brembo’s development activities.

The new disc concept has to be seen in this light. Its production is now extending to the entire range of the Mercedes MRA platform, which combines two different materials: cast iron for the braking ring and thin steel laminate for the disc hat, resulting in a guaranteed weight reduction of up to 15%. Particular attention was also paid to disc aesthetics during 2015, with a restyling of the co-cast disc, which could be extended to the entire product range in the future.

Research, development and testing of non-conventional solutions is ongoing, a process that has also led to a number of patent applications being filed, for application to the cast iron discs or the new generation of “light” discs. These activities include the study of forms, materials, technologies and surface treatments able to meet the needs of the new-generation vehicles, with a particular focus on environmental impact aspects (CO2 and particulates emission, minimising disc wear).

The development of innovative friction materials, complying with future legislative limits and designed for these types of disc, is also highly important. Brembo can be considered to be the only manufacturer with the in-house expertise for this type of development.

STREET MOTORBIKES

xAs far as street motorbikes are concerned, testing is currently taking place on carbon ceramic motorbike discs with new formulations. This testing also involves identifying the best couplings with friction materials that will be defined in the first half of 2016.

The mid-range front cylinder project was successfully completed, and a patent application filed. The prototypes for the functional validation will be prepared in the first few months of 2016. One of the advantages that our customers have also appreciated is the possibility of cylinder customisation with a modest level of investment.

The concept of a combined system for motorbikes, with a rear drum brake and front disc, has been received very positively by the Indian market, also due to the proposed legislation which will make combined systems obligatory in that country on vehicles under 125 cc. Tests on several vehicles have hence been started, with the aim of being able to achieve standard supplies by the first quarter of 2017.

Lastly, magnesium alloy brake levers for road applications were validated during the year and a number of concepts were defined for future top of the range calipers. Moreover a disc concept is being developed that is expected to deliver benefits in terms of feel and comfort.

Activities planned for the first few months of 2016 on motorbike applications: work on acquiring know- how on vehicle dynamics will be completed, and the basic skills defined for future developments; the evaluations of BBW (Brake By Wire) for motorbikes will be further analysed in safety terms, both in-house and working together with customers; a decision will be taken whether to start up development of the first ECS motorbike caliper, adopting concepts and components taken from our experience with car applications.

RACING APPLICATIONS

xWithin the racing applications field, the fine tuning of the new carbon material for F1 and GT applications has been completed and a material developed entirely by Brembo is being used on the track for the first time since 1999. This material has become a benchmark for performance in all the categories where use of carbon is permitted: F1, GT, and IRL (Indy Racing League). The focus for 2015 was aimed at stabilising the production chain and im-proving the mechanical characteristics without reducing system performance. These activ-ities will continue to be the main working areas throughout 2016.

The new disc drive concept used in F1, known as WS (Wide Spline), has enabled the com-posite material to be used, providing higher safety margins than the old drive system. This was tried out successfully on the LMP1 cars (Le Mans Prototype 1) towards the end of 2015. A top team in this category will start the 2016 season directly with the new concept. In addition, work is continuing on the mechanical simulation part of the composite disc for F1/LMP1 applications, after refining the initial simulation methodologies for the thermo-elastic phenomena of the disc and pad material.

At systems level, the new products developed and fine-tuned in recent months continue to be used successfully by the various teams. These include the new hydraulic systems, in particular, offered by Brembo to meet customer needs concerning by-wire braking, which combine with the new power units and energy recovery systems currently allowed by F1 and LMP1 regulations.

BBW systems are currently at the implementation phase for 5 F1 teams. A complete BBW system (an electro-hydraulic Brake by Wire system with integrated solenoid valve) will be implemented with one of these and will be Brembo’s most complete and representative product of such brake control systems.

In the motorbike eld, in the MotoGP class, one team, following on from specific develop-ment contracts, has exclusive use of a new brake caliper containing two ground-breaking concepts that have proved to be particularly interesting and will also be offered to other teams in 2016.

The year 2016 will bring several regulatory changes in the MotoGP class, the most im-portant of which will be the abolition of aluminium-lithium alloys from brake calipers. This regulatory change meant that Brembo had to completely redo all the 2016 systems and the return to the “traditional” material has not been painless: two development cycles were needed to achieve the same performance as the aluminium-lithium system.

Development continues of an “instrumented wheel” system (front and rear) in collabora-tion with the Milan Polythechnic, and one of its spin offs. This is a system that allows en-gineers to obtain information on the torque and the force transmitted to the ground by the tyre. This has proved to be an excellent development tool for correlating telemetry measures, the driver’s feel and the force actually transmitted.

In other projects with Milan Polytechnic, research is currently being conducted to improve the final performance of the rim-tyre system, through an analysis of the two components jointly rather than as two separate objects.

2016 will see a change in tyre supplier for MotoGP (from Bridgestone to Michelin) and Brembo’s instrumented wheel will provide the team, which is developing it with the Group’s technical of ce, with valuable information on the motorbike’s performance with the new tyres.

For the Aeronautic project, after the “APDOA” technical certification was obtained from EASA (European Aviation Safety Agency) in 2014, the early part of 2015 saw Brembo al-so starting the production certi cation process through ENAC, the Italian Civil Aviation Authority.

Development of the design of the complete braking system (calipers, discs, wheels, park-ing brakes and pumps), officially assigned to Brembo in June 2014, is progressing accord-ing to the plan agreed with the customer and passed the Preliminary Design Review (PDR) in early 2015. A new project has also been awarded to Brembo for a complete brake sys-tem for a class CS 23 seaplane.

Partnership contracts continued with several universities (including the above-mentioned Milan Polytechnic and the University of Padua) in pursuit of important goals in various areas of technical development: from electronic control systems to the development of new system concepts, simulations of carbon components, tests of aeronautic components and other subjects.

PADS AND CAPELIERS

xIn addition to calipers and brake discs, Brembo also supplies high-performance, high-reliability and top- quality pads. Brembo Friction is a long-established business which is continuing to develop new materials that best reflect Brembo’s philosophy of innovation and technological development.

The copper-free friction materials, selected by various customers for their high performance, are suitable both for the European market (more demanding in performance terms), and the American market (more demanding as far as comfort is concerned). These materials have been developed both for applications that use cast-iron discs and for those that feature carbon ceramic discs.

In conjunction with the materials for traditional applications, Brembo Friction is developing materials to accommodate the needs of the most recent Brembo calipers such as, for example, those for electric parking brakes.

Brembo’s research is also engaged in identifying solutions for future market needs: motorbikes, heavy commercial vehicles and vehicles for special applications require discs with very high performances and, hence, increasingly intensive development of unconventional friction materials.

For brake pads as well, the company’s focus is on developing lighter materials and innovative components that can help reduce the environmental impact and the emission of CO2 and particulates into the atmosphere.

This also applies to brake calipers, with the development of new solutions including: the use of methodologies to minimise caliper mass for the same performance, the improvement of caliper functionality thanks to new characteristics for the pairing of seal and piston and optimisation of a new-concept pad sliding system.

The product and process improvement work is ongoing in the same way as the search for solutions to reduce mass, increase performance and improve styling. During the first half of the year a study was completed of a new type of caliper with a view to gaining new market segments: the concept approval phase had been finalised and the application development underway with a major European customer.

During 2016 Brembo will be in a position to carry out standard production of a caliper made using aluminium alloy in a thixotropic state (lower temperature than that of casting). The process used, for which a patent has been filed, is named BSSM (Brembo semi-solid metal casting). This technology produces a weight saving, with the same performance, ranging from 5 to 10% and depends on caliper geometry.

In addition, the Technical Development Centres continue to grow as planned in support of Brembo’s expansion in China and the USA, in line with the acquisition of important businesses in these two markets.

Mechatronic products, namely various configurations of electric parking brakes, already approved in-house both for cars and commercial vehicles, are being promoted with Brembo’s customers. In this area, Brembo has been selected by a major European customer to supply a caliper with integrated electric parking brake for commercial vehicles. Production is scheduled to start in 2018.

The ongoing evolution of simulation methodologies is focused on aspects linked to brake system comfort and caliper functionality. Brembo’s current objective is to develop the simulation capacity for the latest brake system component not yet simulated: friction material. From this standpoint, the possibility of using the friction project, thus being able to produce in-house advanced friction materials, is one of the strengths of Brembo which can position itself as a supplier of complete brake systems. On the other hand, the development of a methodology for simulating caliper functionality is aimed at establishing, during the design stage, the caliper characteristics that influence the car’s pedal feel.

ADVANCED R&D AND PROJECTS

xAdvanced R&D activities focus on mechatronic systems for the brake systems of the future and on developing new structural materials. Through these activities, Brembo is preparing to meet market demand expected in the coming years, when the strong drive towards vehicle electrification will result in a significant integration of the brake system with the rest of the vehicle and a constant search for weigth-reduction solutions.

The high level of integration will bring the brake system to dialogue with other vehicle systems, such as electric drive motors and new suspension-steering concepts, and enable an increase in active safety and

optimisation of functions such as regenerative braking. Within this context, Brembo is continuing to develop a Brake By Wire system with the aim of hastening the development of individual brake system components and holding on to its lead as a product innovator. This system concept will be able to be applied to all future vehicles: not only cars, but also commercial vehicles and motorbikes. Additional developments involving system integration are in the study phase for some time now, particularly with electric drive systems and the associated next-generation architecture. In an advanced stage of study is also innovative vehicle wheel-side architecture with electric drive motor and integrated, electronically controlled Brake By Wire

brakes, presented at the last Frankfurt Motor Show. Also within the advanced R&D activities, Brembo continued to cooperate with international Universities and Research Centres with the aim to constantly seek out new solutions to apply to brake discs and calipers, in terms of new materials, innovative technologies and mechanical components. The need to reduce product weight is leading the research function to evaluate the use of unconventional materials, such as technopolymers or reinforced light metal alloys, to produce structural components. These partnerships also extend to methodological activities relating to development, involving the creation and use of increasingly sophisticated simulation and calculation tools.

The Rebrake project funded by the European Union under the Marie Curie programme and coordinated by Brembo together with Stockholm’s Royal Institute of Technology (KTH) and Trento University, is part of these initiatives. This project represents a major step forward for understanding the phenomena linked to tribology, namely the science that studies the behaviour and wear of friction materials, with a particular focus on the PM10 for which there is a 50% reduction target.

The logical continuation of the Rebrake project is represented by the LowBraSys project, which is also funded by the European Union as part of the Horizon 2020 programme. The project started in the second half of 2015 and will last 36 months, involving a consortium of 10 partners with Brembo in the role of coordinator. The methodologies and products partly developed in the Rebrake project will be applied to certain vehicles in this programme, with the aim of concretely proving their efficacy in terms of particulate emission reduction.

The COBRA project is also ongoing. This was launched in 2014 and funded under the “Life +” European programmes, in collaboration with the partners of Kilometro Rosso, Italcementi and Istituto Mario Negri, and with the consultancy firm PNO Italia. The aim of the project is to develop low environmental impact technology aimed at reducing water and energy consumption in the life cycle of the pad component, by replacing organic origin binders (phenol) with cement binders.

Finally, the early part of 2015 saw the funding of the “LIBRA” project, which aims to develop brake pads that use composite material (typically resin), rather than steel, with the ensuing advantage in terms of lightness.

INVESTMENTS

xIn 2015, Brembo’s investment management policy continued to develop along the lines that were followed for the past several years, aiming to strengthen the Group’s presence both in Italy and, above all, internationally. The most significant investments were concentrated in Italy (27%), North America (40%), Poland (15%), China (9%) and the Czech Republic (6%).

Investments in Italy chiefly involved the purchase of production plant, machinery and equipment, in addition to €11,644 thousand for development costs.

As part of its strategy of consolidation and development at the global level, Brembo continued and continue to invest in North America, its preferred industrial hub for expanding and internationalising the Group on the North American market. Several investment plans are currently being implemented in this area:

the construction of a cast-iron foundry in Michigan, close to the new Homer facilities, which will allow Brembo to start a vertical integration process of its production capacity in the United States as well. Work started during the year and will be completed in 2017, making it possible for all production phases to take place in a single site thus guaranteeing a greater efficiency of the production process. The €74 million investment plan will be funded through the Group’s cash generation and will benefit from the incentives provided by the State of Michigan;

the opening of a new foundry and a plant for the processing and assembly of aluminium calipers in Mexico, near Monterrey; on 21 October 2015, the Chairman cut the ribbon of the new plant sitting on over 35 sq m that, once fully operational, will have a production capacity of approximately two million aluminium calipers per year, destined for the major OEM manufacturers in Europe, Asia, United States and Mexico. The investment will total €32 million in the three-year period 2015 – 2017.

In Eastern Europe, investments aimed at increasing production capacity are still underway in the integrated industrial hubs in Dabrowa Górnicza (Poland) and Ostrava-Hrabová (Czech Republic), devoted respectively to the casting and processing of brake discs for cars and commercial vehicles, and the casting, processing and assembly of brake calipers and other aluminium components. A new investment plan was also launched simultaneously and is to be developed from 2014 to 2017, for a total expenditure of approximately €34 million, aimed at building and starting up a new plant in Niepolomice (Poland) specialising in the processing of steel disc hats to be assembled onto the light discs manufactured at the Group’s plants located in Poland, China and the United States.

Group’s total investments undertaken in 2015 at all operations amounted to €155,909 thousand, of which €137,512 thousand was invested in property, plant and equipment and €18,397 thousand in intangible assets.

BREMBOBrake systems

AP RACINGBrake systems and clutches

BREMBObrake systems

MARCHESINIWheels

BREMBO Brake systems

x“Open wheels” Championships

F1

Drivers: Lewis Hamilton - Mercedes

Manufacturers: Mercedes

GP2

Drivers: Stoffel Vandoorne - ART

Manufacturers: ART

GP3

Drivers: Esteban Ocon - ART

Manufacturers: ART

World Series by Renault

Drivers: Oliver Rowland - Fortec

Manufacturers: Fortec

F3 Euroseries

Drivers: Felix Rosenqvist - Prema

Manufacturers: Prema

Verizon IndyCar Series

Drivers: Scott Dixon - Target Chip Ganassi Racing

Team Target Chip: Ganassi Racing

500 miglia Indianapolis

Juan Pablo Montoya - Team Penske

Super Formula Japan

Drivers: Hiroaki Ishiura - Tom’s

Manufacturers: Tom’s

F3 Championship Japan

Drivers: Nick Cassidy - Tom’s

Manufacturers: Tom’s

“Closed wheels” Championships

FIA World Endurance Championship

LMP1 Drivers: Hartley, Webber, Bernhard - Porsche

GTE PRO Drivers: Lietz - Porsche Manthey

Team: Porsche Manthey

GTE AM Drivers: Basov, Bertolini, Shaytar - Ferrari Italia SMP Racing

Team: Ferrari Italia SMP Racing

24 Hours of Le Mans

LMP1: Bamber, Tandy, Hulkenberg - Porsche

LMP2: Howson, Bradley, Lapierre - Oreca

GTE: AM Basov, Bertolini, Shaytar - Ferrari

Tudor United SportsCar Championship

Prototype Team: João Barbosa, Christian Fittipaldi - #5 Action Express Racing Corvette DP

PC Team: Jon Bennett, Colin Braun - #54 CORE Autosport Oreca FLM09

GTLM Team: Patrick Pilet, Bill Auberlen - #25 BMW Team RLL BMW Z4 GTE

GTD Team: Townsend Bell, Bill Sweedler - #63 Scuderia Corsa Ferrari 458 Italia GT3

Pirelli World Challenge GT Series

GT Team: Johnny O’Connell - #3 Cadillac Racing ATS-V R

GTA Team: Frankie Montecalvo - #66 Bayshore Racing DragonSpeed Mercedes-Benz SLS AMG GT3

GT Cup Team: Colin Thompson - #11 Kelly-Moss Motorsport Porsche 911 GT3 Cup

GTS Team: Michael Cooper - #10 Blackdog Speed Shop Chevrolet Camaro

TC Team: Corey Fergus - #00 Motorsports Promotions Porsche Cayman

TCA Team: Jason Wolfe - #36 Wolfe Trucking Kinetic Motorsports Kia Forte Koup

TCB Team: Johan Schwartz - #25 TechSport/CASgroup/Promatex/Serengeti/ ZEROcancer Chevy Sonic

GT3 Blancpain Endurance Series

Drivers: Robin Frijns - Audi WRT

Manufacturers: Audi WRT

SCORE International Overall & Trophy Truck Class

Team: Carlos ‘Apdaly’ Lopez - #5 RPM Racing Chevy Rally Ford F-150

SCORE International Tecate SCORE Baja 1000

Team: Rob MacCachren - #11 Ford F-150

NASCAR Xfinity Series

Drivers: Chris Buesher

Team Ford Roush Fenway Racing

Campionati Rally WRC 2

Team Skoda Motorsport – Skoda Fabia R5

AP RACING Brake systems and clutches

x“Open wheels” Championships

Formula 1

Drivers: Lewis Hamilton - Mercedes

Manufacturers: Mercedes

IRL

Drivers: Scott Dixon - Target Chip Ganassi Racing

500 miglia Indianapolis

Will Power - Team Penske

GP2

Drivers: Stoffel Vandoorne - ART Grand Prix

GP3

Drivers: Esteban Ocon - ART Grand Prix

Formula 3

European Drivers: Felix Rosenqvist - Prema Powerteam

“Closed wheels” Championships

FIA World Endurance Championship

LMP1 Privati Drivers: Beche, Imperatori, Prost - Rebellion - Oreca

LMP2 Drivers: Canal Rusinov - G-Drive Racing - Ligier

24 Hours of Le Mans

LMP2 Drivers: Howson, Lapierre, Bradley - HKG KCMG Oreca 05-Nissan

GTE Pro Class Drivers: Gavin, Milner, Taylor - Corvette Racing C7 R

Nascar

Craftsman Truck Series Drivers: Erik Jones - Kyle Busch Motorsports

Xfinity Series Drivers: Chris Beuscher - Roush Fenway Racing

Tudor United SportsCar Championship

P Class Drivers: Barbossa, Fittipaldi - Action Express - Coyote

LMPC Class Drivers: Bennet, Braun - Core Autosport - Oreca LMPC

ELMS

LMP2 Drivers: Wirdheim, Hirsch, Lancaster - Geaves Gibson

GTC Drivers: Dermont - TDS BMW Z4

BLANCPAIN

GT Drivers: Buncombe, Rep, Chiyo - Nissan GTR Nismo GT3

Manufacturers: RJN Nissan GTR Academy - Nissan GTR Nismo GT3

Open Class

GT Drivers: Parante, Ramos - McLaren 650S

Manufacturers: Toes Martin Motorsport – McLaren 650S

Touring Car

British Drivers: Sheddon - Team Dynamic Honda

Manufacturers: Honda Yuasa Racing - Team Dynamic Honda

DTM Drivers: Wehrlein - Mercedes AMG C63 DTM

WTC Drivers: Lopez - Citroen C-Elysee

Australian V8 Supercar Drivers: Mark Winterbottom - Pepsi Max Crew

Manufacturers: Red Bull Racing Australia

International TCR Drivers: Comini - Seat Leon TCR

Manufacturers: Target Competition - Seat Leon TCR

Japanese Super GT

Classe 500 Drivers: Matsuda, Quintarelli - Nismo Nissan GT-R

Manufacturers: Nismo Nissan GT-R

Classe 300 Drivers: Couto, Chiyo - Gainer Nissan GTR

Manufacturers: Gainer Nissan GTR

Rally Championships

FIA Rally Raid

Drivers: Nasser Al-Attiyah - Mini ALL4 Racing X Raid

Dakar Sud America

Drivers: Nasser Al-Attiyah - Mini Qatar Raid Team

BREMBO brake systems

xMotorbike

Moto GP

Drivers: Jorge Lorenzo - #99 Yamaha Movistar

Manufacturers: Yamaha

Moto2

Drivers: Johann Zarco - #5 Ajo Motorsport

Manufacturers: Kalex

Moto3

Drivers: Danny Kent - #52 Leopard Racing

Manufacturers: Honda

World SBK Championships

World Superbike

Drivers: Jonathan Rea - #65 Kawasaki

Manufacturers: Kawasaki

World Superstock 1000

Drivers: Lorenzo Savadori - #32 Aprilia

Manufacturers: Aprilia

American Superbike

Drivers: Cameron Beaubier

Manufacturers: Yamaha Graves

JSB

Drivers: Katsuyuki Nakasuga

Manufacturers: Yamaha

SBK Drivers: Josh Brookes

Manufacturers: Milwaukee Yamaha

Supersport Drivers: L.Stapleford

GTE Pro Class Drivers: Gavin, Milner, Taylor - Corvette Racing C7 R

CIV

Moto3 Drivers: Marco Bezzecchi - Team Minimoto Portomaggiore - Mahindra MGP30

SBK Drivers: Michele Pirro - Team Barni - Ducati 1199R

SS600 Drivers: Massimo Roccoli - Team Laguna Motoracing - MV Agusta F3

CEV

Moto3 Drivers: Nicolo Bulega - KTM

Moto2 Drivers: Edgar Pons - Pons Racing

FFM

FSBK Drivers: Gregory Leblanc - Kawasaki SRC

FSSP Drivers: Cedric Tangre - Suzuki GSXR-600

Endurance

Superstock Team Traqueur Louit Moto 33

Off-Road Championships

Enduro

E1 Drivers: Eero Remes - TM 250

E2 Drivers: Antoine Meo - KTM 250 sxf

E3 Drivers: Matthias Bellino - Husqvarna 300

EJ Drivers: Jamie MCcanney - Husqvarna 250

Trial

TR1 Mondiale Drivers: Toni Bou - Montesa 4RT Solo pompe freno (vinto anche mondiale indoor)

Rally Raid

Dakar Marc Coma - KTM

Road Race

North West 200 Alistair Seeley - Tyco BMW

Grand Prix Macau Peter Hickman - Briges equipment BMW

MARCHESINI Wheels

xWorld Superbike

Drivers: Jonathan Rea – #65 Kawasaki

Manufacturers: Kawasaki

JSB 1000

Drivers: Katsuyuki Nakasuga

Manufacturers: Yamaha

J-GP2

Drivers: Yuuki Takahashi

Manufacturers: Moriwaki

CIV

SBK Drivers: Michele Pirro

Road Race

Grand Prix Macau Lee Hardy – RAF Reserves BMW

Motocross

Italian drivers championship: Alessandro Lupino – Honda Team Assomotor

Design

x

Brembo car brake disc PVT Plus and brake pad

inspired by Giacomo Balla - Futurism.

Lightweight, greater resistance to thermal cracks and reduced wear on brake pads are the benefits of this brake disc’s new ventilation chamber.

Design

x

Brembo Extrema car brake caliper

inspired by Renè Magritte - Surrealism.

The distinctive traits of Brembo’s Extrema caliper are the result of minimalist, essential design, appearing decidedly more exposed and hollowed out than its predecessors. Illustration by Fabrizio Spadini.

Design

x

Brembo F1 braking system

inspired by Juan Gris - Cubism.

This system is composed of a carbon-fibre disc and six-piston brake caliper. Synergistic studies by Brembo’s engineers and F1 teams allowed the design of the ventilation holes to be taken to the extreme, with a clear improvement in heat dissipation.

Design

x

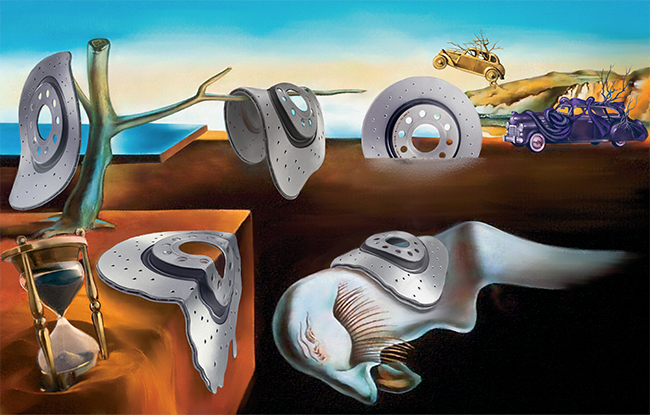

Brembo Sport car brake disc

inspired by Salvador Dalì - Surrealism.

The special holes on the braking surface disperse water in wet driving conditions, thus improving the responsiveness of the brake system.

Design

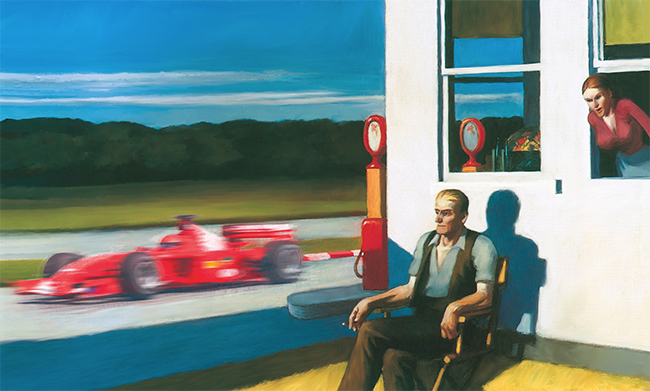

x

Brembo F1

Inspired by Edward Hopper - American realism.

Illustration by Fabrizio Spadini.

Design

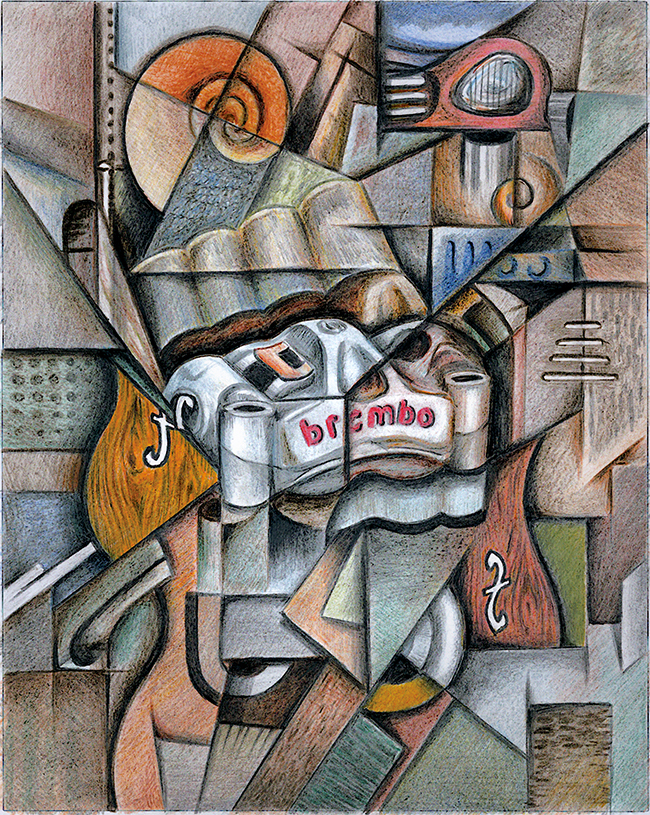

x

Brembo M-50 motorbike brake caliper

Inspired by Pablo Picasso - Cubism.

This caliper is the result of the use of sophisticated “topological optimisation” calculation programmes, permitting the removal of material from parts of the caliper where it is not needed, so as to get as close as possible to the optimal structure, which combines the maximum rigidity with the lowest weight. Illustration by Luca Savorani.

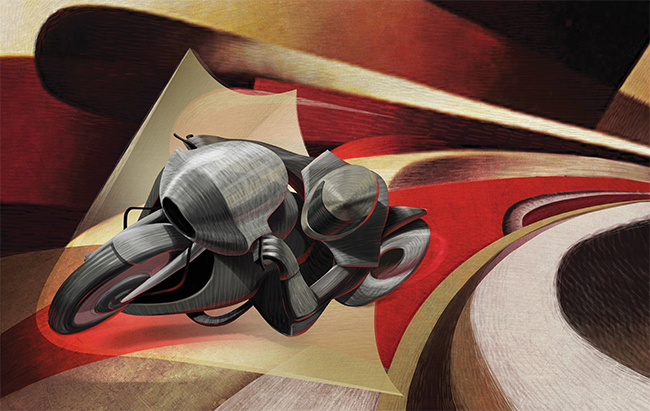

Design

x

Brembo moto GP

Inspired by Fortunato Depero - Futurism.

Illustration by Fabrizio Spadini.

Design

x

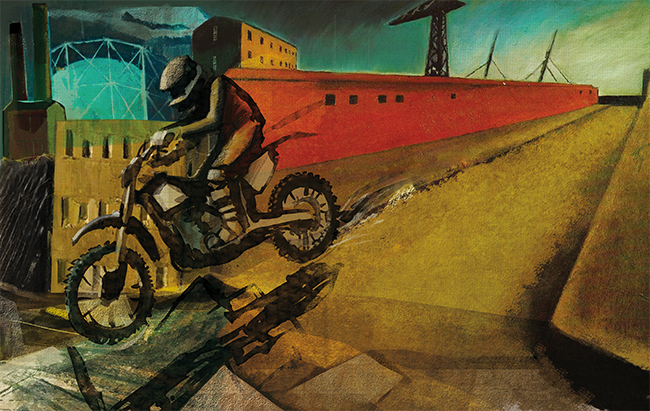

Brembo motocross

Inspired by Mario Sironi - Novecento Italiano.

Illustration by Fabrizio Spadini.

Design

x

Aluminium Genesi Marchesini motorbike rims

Inspired by Giacomo Balla - Futurism.

Multidirectional forging of the aluminium alloy and the use of optimised dies for final wheel geometry yield a very light material with exceptional mechanical characteristics. Illustration by Luca Savorani.

Design

x

Brembo Sport car brake disc

Inspired by Salvador Dalì - Surrealism.

The special holes on the braking surface disperse water in wet driving conditions, thus improving the responsiveness of the brake system. Illustration by Maurizio Tacqui.

Design

x

Brembo’s four-piston car brake caliper

Inspired by Giorgio De Chirico - Metaphysical Art.

This geometry allows for an 8% decrease in mass, due to the smaller amount of material used in the points subject to the least stress, and thus permits higher fuel efficiency and reduced emissions.

Design

x

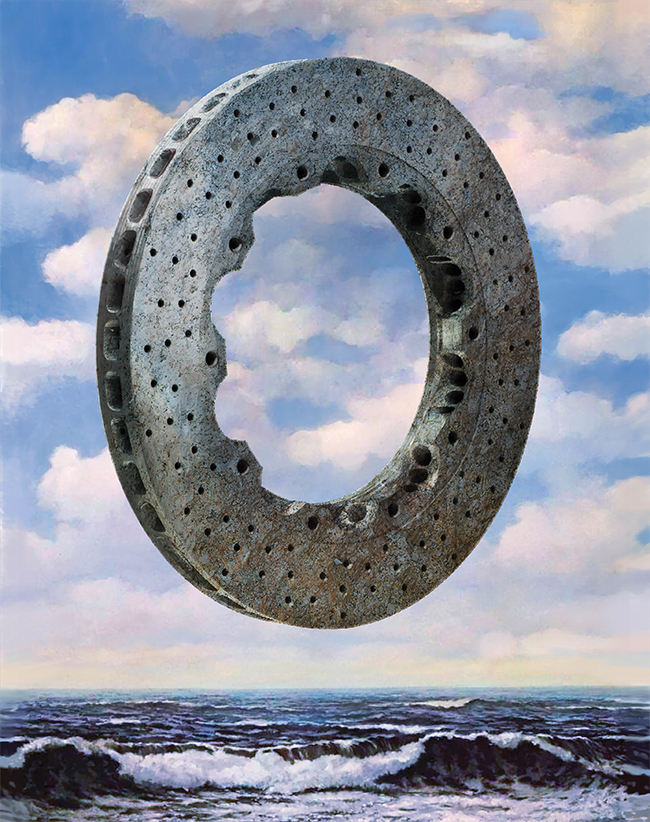

Brembo CCM car brake disc

Inspired by René Magritte - Surrealism.

The carbon ceramic material offers advantages in terms of performance on wet and dry surfaces, weight, comfort, corrosion resistance and durability.

Design

x

motorbike disc and caliper Harley Davidson Night Rod Special

Inspired by Keith Haring - Graffiti Art.

Safety and control, braking power and extreme performance in all situations. The speed sensor has been ably stylised, ensuring an efficient motorbike design in the classic Harley style.

Design

x

Brembo 14 RCS motorbike brake master cylinder

Inspired by Giorgio De Chirico - Metaphysical Art.

Powerful braking capacity that can be adapted to road and weather conditions, the driver’s sensibilities and feel with the motorbike thanks to the RCS (Ratio Click System). Illustration by Fabrizio Spadini

Design

x

Brembo B-M8 car brake caliper

Inspired by Tom Wesselmann - Pop Art.

The Brembo B-M8 caliper won the Engineered New Product Award 2015 for innovation in the field of engineering and advancing in the technological state of the art.

Design

x

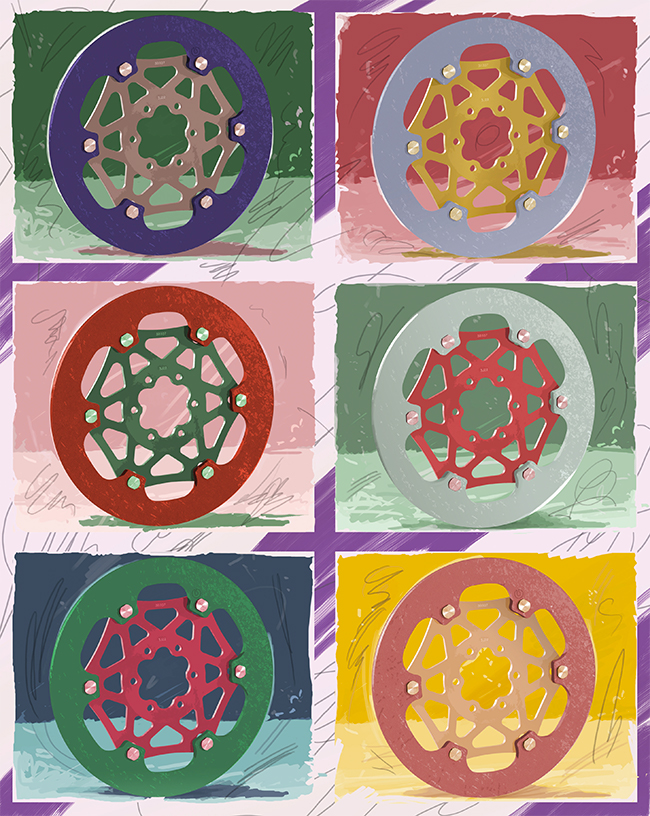

Brembo MotoGP brake discs

Inspired by Andy Warhol - Pop Art.

These carbon discs are distinguished by their very fine tolerances in the order of just a few microns. The special configuration allows the braking torque to be transferred more effectively whilst also improving resistance to thermo-mechanical stress. Illustration by Maurizio Tacqui.

Design

x

Brembo B-M8 car brake caliper

Inspired by Roy Lichtenstein - Pop Art.

4D technology has allowed Brembo to devise a completely different design from the approach typically taken to this type of caliper.

Design

x

Brembo B-M4 car brake caliper

With its exclusive, innovative design, the B-M4 brake caliper, along with the B-M8, are the first members of a new family of calipers that will make the new Brembo High Performance kits stand out on the market. Graphic elaboration by Simona Bonora

Brembo S.p.A. | P.IVA 00222620163 | RSS Feed

Downloads

x